Though the grocery store may only carry yellow or white popcorn home gardeners know that popcorn comes in variety of colors. You may also know that popcorn can be used in a variety of ways. In fact, popcorn was probably first ground like other flour corns to make bread. Native Americans had domesticated popcorn by 5000 B.C.E. but as far as currently available archeological evidence suggests, popping popcorn as we do today didn’t become popular until the 1820s.

Check out the PBS article, History of Popcorn, for more interesting information.

Harvesting

Popcorn should be left to dry in the field as long as possible. When you harvest, the husks should be completely dry and the kernels hard. You should then dry your corn as soon as possible.

Drying

Once you’ve harvested your popcorn, it should be hung somewhere cool and dry. An easy way to do this is to pull the husks back, remove the strings, and hang them on a line with clothespins either indoors or under cover. Some folks also have luck completely removing the husks and hanging mesh bags of ears. Especially if you live in a humid climate, be sure to move the bags around every few days and check for signs of mold or mildew where the ears of corn touch eachother.

Popcorn needs to dry until it reaches an ideal moisture content of between 13 and 14%. This level of moisture is key to getting good “pops.” While your popcorn is hanging to dry test a few kernels once or twice a week. When they pop well you can move your popcorn to storage.

If you just can’t wait to eat a bit you can speed up the process with a dehydrator. Shell a few ears and lay the kernels on a dehydrator tray. Dehydrate between 120-130°F, checking few hours until it’s popping well.

Storing

To save space, shell your popcorn and place it in airtight containers. It will keep for several years.

If stored popcorn won’t pop it may have become too dry. Don’t worry though, you can add moisture to make it pop again. Fill a quart jar with popcorn and 1 tablespoon of water. Shake occasionally until all the water is absorbed. Check to see if it will pop every 3 to 4 days and keep adding water 1 tablespoon at a time until it pops well.

Popping

Making popcorn on a stovetop is surprisingly easy. Begin by heating a large, thick-bottomed saucepan or dutch oven with lid with about 3 Tbs of olive oil in it over medium heat. Once hot, the oil should cover the bottom of the pan. Then add 3 kernels to the pan and place the lid on.

When all the kernels have popped, add 1/3 cup of kernels and place the lid back on. Ocassionally slide or shake the pan back and forth redistributing the popcorn. When the popping slows to a few seconds between pops remove your pan from the heat and enjoy!

Other Uses

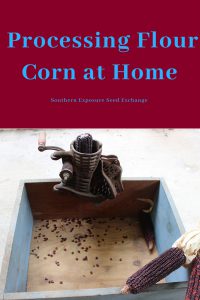

Popcorn also makes wonderful cornmeal or grits. Check out our article about proccessing flour corn for tips. You can also make popcorn pie!

Additionally popcorn can be eaten like sweet corn in what’s called the “milk stage.” When the husks are still green but the silks have begun to brown check an ear or two to see how the kernels look. For colored popcorns it’s ready just before it takes on darker colors. You can also check by tasting it or by piercing a kernel with a fingernail. If white liquid comes out it’s ready for fresh eating.